Laser Marking/Engraving

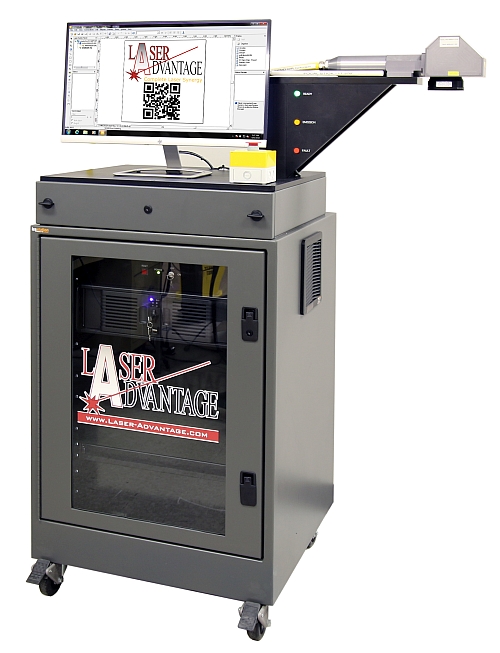

Laser Advantage UVM laser marking system

Laser Advantage UVM laser marking system

The use of laser marking and laser engraving is in demand, mainly as a result of government requirements that call for readable product and part identification. Laser marking uses a focused beam causing the material under the surface to oxidize, or turn black. The result is a high contrast image that is permanent and resistant to wear. This process is used to apply a variety of information, including serial numbers or product codes. It does not corrupt the material’s surface, it cannot be washed off and is not susceptible to abrasion. Every design can be reproduced at the same high quality and lasers provide the level of detail you cannot get with printing.

Laser marking systems are self-contained, and are comprised of a laser, power supply, controller and software. Fiber lasers are by far the most flexible being able to mark and engrave a variety of materials. Some parts or materials cannot tolerate mechanical engraving thus laser marking offers the perfect non-contact solution. This is particularly critical when used for marking medical devices, where any indentations are undesirable. For that reason, the FDA must approve the marking method used by the medical industry in the manufacture of instruments or implantable devices. Laser marking is normally performed on metals but also used on plastics.

Laser marking on aluminum pill bars

Laser marking on aluminum pill bars